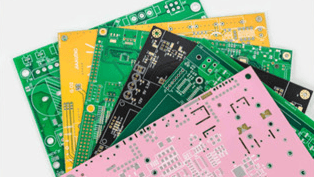

PCB Prototype & PCB Fabrication Manufacturer

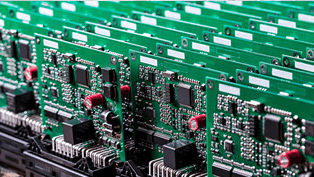

When building electronics, your circuit board is the heart of the system. It connects everything—from sensors and chips to power supplies and outputs. Before mass production, most engineers need a PCB prototype to test their ideas. Once the prototype is approved, you move to PCB fabrication for larger quantities.

Working with a professional PCB prototype and fabrication manufacturer saves time, reduces rework, and ensures reliability. That’s why thousands of engineers trust Thindry—a certified PCB manufacturer focused on speed, quality, and support.

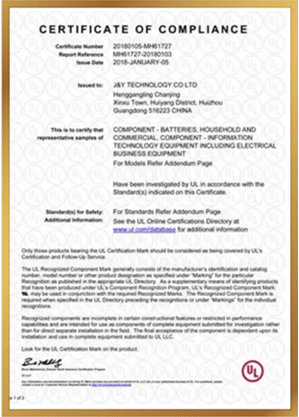

We specialize in prototypes and full-scale production for medical, automotive, aerospace, industrial, and consumer electronics. With certifications like ISO9001, UL RoHS, and a complete MES traceability system, we guarantee your boards meet the strictest requirements.

What Is a PCB Prototype?

A PCB prototype is a small batch of circuit boards used for testing and design validation. You can spot layout issues, fix functional problems, and test firmware before full production.

Prototypes are often made in small runs—1 to 20 pieces—and can be made with simpler processes or full production-grade specs. At this stage, speed is critical. That’s why top manufacturers offer quick-turn prototyping, often within 24 to 72 hours.

What Is PCB Fabrication?

PCB fabrication refers to the full manufacturing process of printed circuit boards, including:

- Preparing the base material (FR4, aluminum, ceramic, etc.)

- Layer stacking and lamination

- Drilling holes and vias

- Etching copper traces

- Solder mask application

- Surface finishes (ENIG, HASL, OSP, etc.)

- Final routing and inspection

Whether for prototypes or high-volume batches, every step must be precise to ensure the board functions as expected. Errors in fabrication can cause failures in real-world applications, so picking the right PCB fabrication manufacturer is essential.

Why Choose Thindry Circuits for Your PCB Needs?

We combine speed, precision, and customer service to deliver value at every stage of your product lifecycle.

Item |

Capability |

PCB Types |

Rigid, Flex, Rigid-Flex, MCPCB, Ceramic, HDI |

Lead Time |

As fast as 24 hours for prototypes |

Certifications |

ISO9001, UL, RoHS |

Minimum Trace/Space |

4/4 mil |

Via Capabilities |

Microvia, blind/buried, via-in-pad |

Surface Finishes |

ENIG, ENEPIG, HASL, Immersion Tin/Silver, OSP |

Panel Size |

Up to 600mm × 1200mm |

Online Quote System |

Yes, with engineering check |

DFM & DFA Support |

Included, with personal feedback |

MES Traceability |

Full component and process tracking |

We support over 3000 engineers, startups, and Fortune 500 companies worldwide.

Common Applications We Support

Our PCB fabrication services cover a wide range of industries:

- Medical devices: Patient monitors, wearable trackers, surgical tools

- Automotive electronics: EV battery management, inverters, control modules

- Aerospace systems: Satellite subsystems, flight control boards

- Industrial automation: PLCs, sensors, high-voltage PCBs

- Consumer electronics: Smart wearables, drones, audio products

Whether you’re building for performance, precision, or price—our boards perform under pressure.

How Thindry Circuits Supports Global Clients?

Global teams face challenges: time zones, shipping delays, and unclear specs. At Thindry, we solve that by providing:

- 24/7 response support with experienced engineers

- Dedicated account managers who speak fluent English

- Fast prototyping in 1–3 working days

- Transparent order tracking with MES system

- Global shipping through DHL, FedEx, or air freight

Clients in Europe, North America, Southeast Asia, and the Middle East rely on us to keep their projects on time. We’ve supported projects in IoT, EV, medical imaging, and military-grade electronics.

What Files You Need to Provide?

To get your PCB prototype or fabrication order started quickly, you’ll need to provide a few essential files. These files allow engineers to understand your design and begin manufacturing without delays. The most commonly required files include:

- Gerber Files: These are the standard files for PCB fabrication. They include copper layers, solder mask, silkscreen, and outline.

- Drill File (Excellon format): This tells us where to drill holes and their diameters.

- Bill of Materials (BOM): If you’re also requesting assembly, include a BOM listing all components with part numbers and descriptions.

- Pick & Place File (Centroid File): SMT assembly product must provide.

- Readme or Fabrication Notes: Include a simple text file explaining any special instructions—such as surface finish, impedance control, or copper thickness.

If you’re not sure which files to include, don’t worry—our engineers will review everything and guide you through it. Just upload what you have, and we’ll help fill in the gaps.

How to Get a PCB Quote Easily?

Getting a PCB quote should be simple. At Thindry, we’ve made it easy:

- Upload your Gerber files on our website.

- Choose your board specs: layers, thickness, copper weight, finish.

- Add notes about special features like blind vias or impedance control.

- Our engineers review your design, check for errors, and send a quote.

We support your product from early development, components sourcing to mass production. Start with a fast prototype, and we’ll keep the same design file, quality standards, and process control when you’re ready for volume.

Thindry delivers fast turnaround, expert support, and strict quality control so your boards work the first time, every time.

FAQs

1. What’s the fastest lead time for PCB prototyping?

We offer same-day delivery for urgent prototype orders, depending on board complexity.

2. Can I order a prototype and then scale to full production with the same vendor?

Yes. We handle both small prototype runs and mass production in-house with consistent quality.

3. Do you support ceramic PCBs for RF or LED applications?

Absolutely. We specialize in ceramic PCB fabrication, including aluminum nitride and alumina options.

4. What if I need blind vias or via-in-pad designs?

We support advanced via technologies, including HDI, microvias, and via-in-pad.

5. Can you help me with PCB assembly too?

Yes, of course! We offer turnkey PCB assembly including sourcing components, SMT/DIP, testing, and final packaging.